Popular products

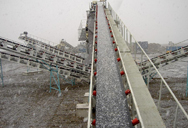

La configuration de 30-50tph li

- quipement: Y3S23G93E46Y55B Lieu dutilisation: Mafikeng, Afrique du Sud Heure dutilisation: Depuis Jui

250-300t/h ligne de concassage

- La Configuration de la ligne de concassage mobile de gangue de charbon Kurtz buss la RussieEquipement

200-250 MTPH Projet de Concassa

- Les configurations de 200-250 MTPH Projet de ConcassageCriblage Mobile de Manganse Johannesburg Type

50-80tph ligne de concassage ba

- La configuration de 50-80tph ligne de concassage basalte mobile au Venezuelaquipement: Un concasseur

50-80tph ligne de concassage ba

- La configuration de 50-80tph ligne de concassage basalte mobile au Venezuelaquipement: Un concasseur

80-120tph projet de concassage

- Les configurations de 80-120tph projet de concassage mobile de pierre de la rivire au Kirghiziaquipem

250tph projet de concassage mob

- Les configurations de 250tph projet de concassage mobile de minerai de fer la Zambiequipement : deux

250tph ligne de production de g

- La configuration de la ligne de production de granite de 250tph en RussieEquipement: Trois stations m

120tph projet de concassage cal

- La configuration du projet de concassage calcaire mobile de 120tph pour la construction au Mexiquequi

300tph ligne de concassage mobi

- La configuration du 300tph ligne de concassage mobile de granit au Nigeriaquipement: Deux stations mo

300tph ligne de concassage de p

- La configuration du 300tph ligne de concassage de pierre au Qatarquipement: Station mobile YG1142E710

La ligne de concasseur mobile d

- La configuration de la ligne de concasseur mobile de pierre dure à capacité de 80-100TPH en Columbi

Coal mill, gypsum mill, clay mill, etc. Pfeiffer MPS mills

Gebr. Pfeiffer offers the MPS vertical roller mill for grinding, drying, calcining and classifying coal, petcoke, gypsum, clay, limestone, quicklime and more. The MPS mill is a versatile, energy-efficient and reliable machine with low capital and

More

Vertical roller mill designed and built for flexibility - Qlar

The Raymond Bowl Mill is considered the finest vertical roller mill available for pulverizing coal. The typical Raymond bowl mill system is designed to simultaneously dry, pulverize, and

More

How Does a Vertical Coal Mill Work

2024年3月16日 A vertical coal mill is a type of industrial milling equipment used to crush and grind coal into powder for use in thermal power plants and the cement industry, featuring a vertical structure that facilitates efficient pulverization and energy saving.

More

Coal Mill in Cement Plant Vertical Roller Mill Air

The most used coal mills in cement plants are air-swept ball mills and vertical roller mills. At present, most cement plants use coal as the main fuel in the clinker production process. The standard coal consumed by the new dry

More

Used Raymond Mills Roller, Vertical, Bowl For Sale Machinery ...

ME buys sells Used Raymond Mills including rollers mills with whizzers, vertical mills, bowls mills and other mill types. Request a quote today. Buy Equipment; Sell Equipment; ... Mill, Raymond, Bowl, Mdl 573, 26,000# coal/hr #C738790. Request a Quote. Buy Equipment; Current Liquidations; Sell Equipment; Can't Find?

More

Vertical Mills for sale listings - MachineTools

Milling Machines - Vertical Mills for sale listings - We have 365 listings for Vertical Mills listed below. Find items by using the following search options. You can also click on the column heading to sort through the listings. For more information on an item, contact the seller directly.

More

Vertical Coal Mill - Great Wall

Vertical Coal Mill, also known as coal mill, for superfine grinding of raw coal, soft coal specifically for cement, power plant, steel mill and other fields. Its special design structure and production process creates the higher production efficiency with lower energy consumption, less dust, lower noise than ball mill, which meets national standard of energy saving industry.

More

How does a Coal Mill Work? - ball mills supplier

Coal is a vital source of energy in many industries worldwide. From power generation to manufacturing, coal is used in various processes. However, before it can be used, coal needs to be processed in a coal mill. In this article, we will explore the basics of how a coal mill works. Introduction Coal mills are []

More

Energy-saving and Efficient Vertical Roller Mill Fote Machinery

Pre-sale service. Sales service. After-sales service. Tip1: The specific time arrangement depends on the actual situation. ... To meet the needs of customers, we have equipped them with 3 vertical coal mills, each with a capacity of 30 t/h. Material: Anthracite, lignite

More

Reliable Coal Pulverizers and Mills » Babcock Wilcox

Reliable coal pulverizer performance is essential for sustained full-load operation of today's power plants. An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW.. BW's pulverizers, found at power stations throughout the world.

More

Boiler Mill and Coal Pulverizer Performance GE Steam Power

Can GE service my boiler mills?. YES. Our boiler mills and coal pulverizers span the globe and are built in a variety of sizes and capacities.We provide customized maintenance solutions, and offer a full spectrum of high-quality solutions for each—in addition to our thousands of standard boiler mill parts and boiler service solutions.This is the Power of Yes.

More

Vertical roller mills FLSmidth Cement

Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs. What’s more, our online condition monitoring services enable you to adopt a proactive maintenance strategy for your OK™ and

More

Vertical Coal Mill Crusher Mills, Cone Crusher, Jaw Crushers

Caiman Vertical roller coal mill for coal grinding plant. Vertical roller coal mill main characteristics. 1, High efficiency grinding of coal, oil, lignite coke, anthracite, etc. 2, Dynamic Rotary separator provides high

More

Vertical Milling Machine - New or Used Vertical

There are 25 Vertical Mills for sale in Australia from which to choose. Overall 61% of Vertical Mills buyers enquire on only used listings, 39% on new and 5.55% on both new and used Vertical Mills items. Buyers usually enquire on

More

The layout of the coal mill with a rotary classifier.

Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size. Rotary kilns then use the powders as fuel burners. The VCM has a housing section equipped with a lining ...

More

Coal Vertical Roller Mill (VRM) for Grinding Stone

Vertical roller mill can replace ball mills or tube mills used for preparing coal. Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding. Grinding media wear in a VRM will only be 5 to 10 g/ton of coal powder, as compared to 100 g/ton of coal powder in

More

Ball Mill for Sale Cement Mining and Chemical Equipment

2024年3月22日 Pre-Sale Service. AGICO CEMENT manufacturers provide one-stop services: pre-sale consultation and selection, scheme planning and design, ... Vertical coal mills are renowned for their high resistance rate, ensuring longevity in operation while maintaining stable operating conditions, thus.

More

Vertical Coal Mill Magotteaux

As a leading innovator with power station technologies – and other industries that need to process coal, Magotteaux is the ideal firm to turn to when seeking cutting-edge vertical coal mill technology.Our tires and tables mean that vertical coal mills can run more efficiently than ever before.In many cases, there is a compromise that needs to be made between the length of

More

Vertical roller mill, Vertical roller grinding mill - DirectIndustry

Find your vertical roller mill easily amongst the 14 products from the leading brands (FLSmidth Dorr-Oliver Eimco, FLSMIDTH, ...) on DirectIndustry, the industry specialist for your professional purchases.

More

Vertical Mills 3-Axis Vertical Milling Machines More for Sale

JET Vertical Mills are precision-built and designed to last. When picking a 3-Axis Vertical Milling Machine or any other type, JET has a large range of options that will suit your needs. View as Grid List. Items 1-15 of 408.

More

LOESCHE-MILLS

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin. 1953 500th coal mill plant sold worldwide. 1961 Introduction of hydraulic spring assembly system. 1965 Construction of first pressure mill (LM 12.2 D). 1980 Delivery of first modular coal mill (LM 26.3 D). 1985 Delivery of first self-inerting coal grinding plant (LM 21.2 D) for the steel industry (PCI ...

More<< Previous:Comment Réduire Ou Contrôler Le Bruit Du Broyeur à Boulets

>> Next:Materiel Dextraction De Minerai De Fer Usage Inde