Popular products

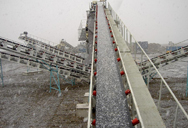

La configuration de 30-50tph li

- quipement: Y3S23G93E46Y55B Lieu dutilisation: Mafikeng, Afrique du Sud Heure dutilisation: Depuis Jui

250-300t/h ligne de concassage

- La Configuration de la ligne de concassage mobile de gangue de charbon Kurtz buss la RussieEquipement

200-250 MTPH Projet de Concassa

- Les configurations de 200-250 MTPH Projet de ConcassageCriblage Mobile de Manganse Johannesburg Type

50-80tph ligne de concassage ba

- La configuration de 50-80tph ligne de concassage basalte mobile au Venezuelaquipement: Un concasseur

50-80tph ligne de concassage ba

- La configuration de 50-80tph ligne de concassage basalte mobile au Venezuelaquipement: Un concasseur

80-120tph projet de concassage

- Les configurations de 80-120tph projet de concassage mobile de pierre de la rivire au Kirghiziaquipem

250tph projet de concassage mob

- Les configurations de 250tph projet de concassage mobile de minerai de fer la Zambiequipement : deux

250tph ligne de production de g

- La configuration de la ligne de production de granite de 250tph en RussieEquipement: Trois stations m

120tph projet de concassage cal

- La configuration du projet de concassage calcaire mobile de 120tph pour la construction au Mexiquequi

300tph ligne de concassage mobi

- La configuration du 300tph ligne de concassage mobile de granit au Nigeriaquipement: Deux stations mo

300tph ligne de concassage de p

- La configuration du 300tph ligne de concassage de pierre au Qatarquipement: Station mobile YG1142E710

La ligne de concasseur mobile d

- La configuration de la ligne de concasseur mobile de pierre dure à capacité de 80-100TPH en Columbi

Recovery of gold from sulfide refractory gold ore: Oxidation

2021年4月1日 The main contributions are described as follows: (1) A complete process of gold recovery from sulfide refractory gold ore was proposed and the gold was effectively

More

ALTA Gold 2012 E-Doc - Glencore Technology

Review existing mineralogy and testwork data. Review possible refractory gold flowsheets. Conduct a preliminary comparative assessment of the options. Develop conceptual level

More

A typical flowsheet for processing refractory gold ore

Download scientific diagram A typical flowsheet for processing refractory gold ore (Sulphidic Gold Ore). Numbers represent unit operations and sample points in red.

More

Flowsheet Development of A Refractory Gold Ore To Minimise

Testwork was undertaken to develop a flowsheet that would maximise gold recovery from an ore containing 3 g/t Au and high levels of arsenic. Treatment of the sulphide ore involves gravity

More

Process Flowsheet Selection - ScienceDirect

2016年1月1日 While refractory characteristics can be seen in a variety of ore types, including auriferous base metals and rocks with a high carbon content, the major focus in refractory

More

Establishing thE ProcEss MinEralogy of gold orEs - SGS

It provides useful information on process selection, flowsheet development, recovery improvement and reagent consumption optimization. By combining classic mineralogical

More

Gold-bearing arsenopyrite and pyrite in refractory ores: analytical ...

Gold bonding in arsenopyrite, examined by transmission electron microscopy, is shown to be dispersed within the FeAsS crystal structure. Typical growth patterns and As-Au diffusion

More

Biological Leaching-Pressure Oxidation for Auriferous

Based on extensive bench scale testwork and pre-vious pilot plant campaigns, the recom-mended process flowsheet is illustrated in Figure 1. As a part of the bankable feasibility study, TVX

More

Ultra Fine Grinding - A Practical Alternative to Oxidative Treatment

This paper details the operation of the ultra fine grinding process at KCGM as a non oxidative treatment for the extraction of gold from a refractory ores. The refractory nature of gold ores

More

Potential pre-treatment and processing routes for recovery of

Potential pre-treatment and processing routes for recovery of gold from complex (refractory) gold ores. A review. The depletion of high grade and easily extractable gold ores has

More

Cyanidation of Refractory Gold Ores: A Review

2014年7月30日 In mineral processing, gold ores are commonly classified as (i) free-milling, (ii) refractory gold, and (iii) complex gold ore types, where the free-milling ore type has high gold recovery (>90% ...

More

FLOWSHEET ASSESSMENT TO RECOVER MORE

2011年1月1日 The gold mining industry has mainly relied upon the use of highly polluting chemicals, such as mercury and cyanide to recover gold from its ores. The Coal Gold Agglomeration (CGA) process was ...

More

Gold Process Mineralogy - SGS

processing techniques required, gold . ores are commonly classified into two major ores. Typically, free-milling ores are defined as those where over 90% of gold can be recovered by conventional cyanide leaching. Refractory ores give low gold recoveries only with the use of significantly more reagents or more complex pre-treatment process. 1 ...

More

Mineralogical Investigation of Gold Ores - ScienceDirect

2016年1月1日 The process mineralogy of gold is not limited to the gold minerals, submicroscopic gold, and their carriers but also includes the study of gangue minerals and other species that may affect gold processing, such as cyanicides. [Ed.: See also Chapter 6, covering the geometallurgical characterization and automated mineralogy of gold ores.]

More

Processing technologies for gold-telluride ores International

2010年2月12日 Gold telluride ores are important gold refractory ores due to the presence of sulfides and other gangue materials. The classification and main physical properties of gold telluride ores were described, and possible treatment methods including flotation, leaching, and oxidation were reviewed. The results show that flotation procedures are much easier for gold

More

Flotation behaviour of gold during processing of porphyry copper-gold ...

1997年9月1日 The gold distribution in the ores from Nevada and the Pacific Rim are shown in Table 4. 100 95-- 0 Ore from Nevada 90.4 0Ore from Indonesia 85 80 75- 0 70-: 65 0.5 1 1.5 2 2.5 3 Graphitic carbon in ore, [%] Fig.13 Effect of graphitic carbon in the ore on the recovery of gold TABLE 4 Gold Distribution in Carbonaceous SulphWe Ores Mineral Ore from Nevada Ore

More

FLOWSHEET DEVELOPMENT FOR GOLD OREBODIES - SGS

FLOWSHEET OPTIONS CRUSHING FOLLOWED BY DUMP OR HEAP LEACHING WITH CYANIDE This method of gold recovery is the preferred method for treating low-grade gold ores because of its low cost. Between 10-20% of the gold recovered each year from primary sources is extracted by this technique. The advantages of this process are: • Simplicity

More

Characterisation of tectonic refractory gold ore - ResearchGate

2014年9月28日 A typical flowsheet for processing refractory gold ore (Sulphidic Gold Ore). Numbers represent unit operations and sample points in red. QXRD results of ROM, FC, BIOX® U, BIOX® L and BIOX® H.

More

(PDF) Metals Special Issue: A Review of the Cyanidation Treatment

2020年7月5日 In the case of processing refractory gold ores and concentrates, bioleaching makes it possible to recover gold through the destruction of gold-bearing minerals (pyrite, arsenopyrite) due to the ...

More

Flowsheet Options For Processing Copper Gold Gold Copper Ores

The processing of gold copper and copper gold ores can be highly problematic, site specific and the process selection is dependent on ore grade, mineralogy, acid leach behaviour, cyanide chemistry, product saleability and environmental considerations.

More

Gold-bearing arsenopyrite and pyrite in refractory ores: analytical ...

Gold-bearing arsenopyrite and pyrite in refractory ores: analytical refinements and new understanding of gold mineralogy - Volume 71 Issue 2 Our systems are now restored following recent technical disruption, and we’re working hard to catch up on publishing.

More

Recovery of gold from sulfide refractory gold ore: Oxidation

2021年4月1日 Sulfide gold ores account for a large proportion of refractory gold ores, therefore, it is very meaningful to recover gold from sulfide gold ores (Ubaldini and Vegliò, 2000, Saba, 2011, Hammerschmidt, 2016). Moreover, the major gold leaching process for extracting gold from ores and concentrates is still cyanide leaching.

More

Gold Extraction from a Refractory Sulfide Concentrate

2023年1月12日 Many gold deposits contain finely disseminated gold particles in iron sulfide minerals such as pyrite. These minerals are called refractory gold ores because of the presence of gold, which occurs either as disseminated

More

Lime use in gold processing – A review - ScienceDirect

2021年12月1日 Most refractory gold ores, however, are deemed refractory because the fine gold particles are contained and occluded within a matrix of sulfide minerals, most commonly pyrite (FeS 2) or arsenopyrite (FeAsS), or when the gold is in solid solution with other minerals, typically sulfide minerals.

More

17 - Flotation of Gold Ores - Aalto

coarse. Some deposits contain up to 3% pyrite. Size of the gold contained in pyrite ranges from 0.01to 0.07 μm Hydrothermal This type contains a variety of ores, including(a) gold-pyrite ores, (b) gold-copper ores, (c) gold-polymetallic ores and (d) gold oxide ore, usually upper zone of sulphide zones. The pyrite content of the ore varies from

More

Mineral Processing of Rare Earth Ores SpringerLink

2020年3月26日 2.2.1 Occurrence. Rare earth minerals occur as fluorites, oxides, tantalates, carbonates, phosphates, sulfates, borates, silicates, etc. (Qi 2018).List of different rare earth minerals are presented in Table 2.3.The average concentration of REEs in the earth’s crust is found to be 150–220 ppm, which is much higher than the concentration of other base metals

More

Integrated Technology for Processing Gold-Bearing Ore

extraction of gold from these ores is of particular impor-tance for all gold-mining and processing countries in the world [3], since the reserves of placer gold are depleted, oxidized ore is easily processed and the strategic needs to increase the size of difficult-to-process ores, while it should be kept in that reserves of these ores make up ...

More

A systematic review of sustainable gold extraction from raw ores

2022年3月1日 Refractory character is determined by the gold's ultra-fine occlusion inside sulfide minerals, particularly pyrite and arsenopyrite. ... The aim of this paper is to present a systematic review of the mineral processing of gold ores, with special focus on alternative leaching reagents to cyanide that can facilitate more sustainable ...

More

8 Types of Gold Ore - Properties and Ways to Process

2023年6月12日 The most valuable ores of gold are quartz gold ore, silver gold ore, copper gold ore, gold sulfide ore, etc. Home; Equipment. All Equipment; Stone Crushing Machine; ... 1 A common practice in processing pyrite gold ore is to remove as much gold and sulfide as possible by gravity treatment and/or flotation.

More<< Previous:Bcvl 002 Concasseur De Verre

>> Next:Concasseur En Tanzanie France